Wind farms can generally be broken down into 2 separate areas of construction:

- Turbines: supply, installation and commissioning of wind turbines and towers

- Balance of Plant (BoP) works: everything else needed except the turbines (foundations, substations, cabling, etc.)

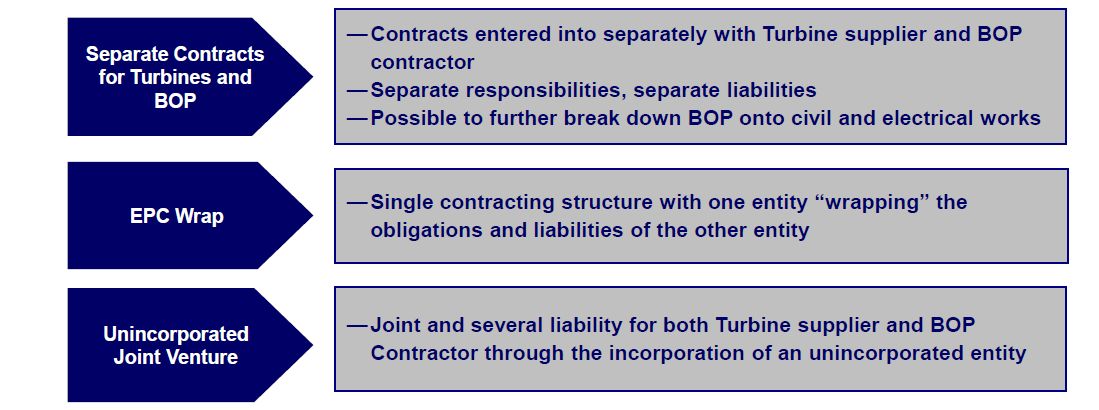

Several option are available to the developers:

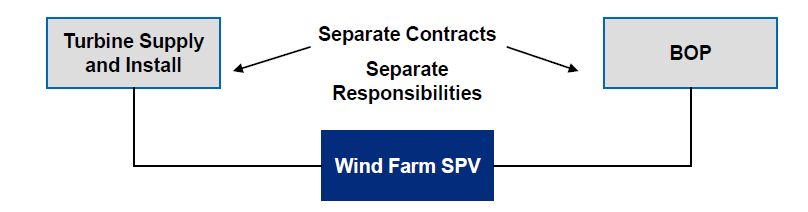

The first option is that the wind farm Special Purpose Vehicle signs separate contracts for BoP and Supply and Installation:

If two or more separate contracts are signed, the interface risk is taken by developer.

Warranties are backed by the balance sheet of each contractor, clearly only for the works undertaken. In exchange for this risk taken by the developer, substantial savings are possible and a broader range of participant to the tender is possible.

Moreover, the project management will be more complicated and sometimes it is difficult to attribute the source of a delay or to define de interface between obligations.

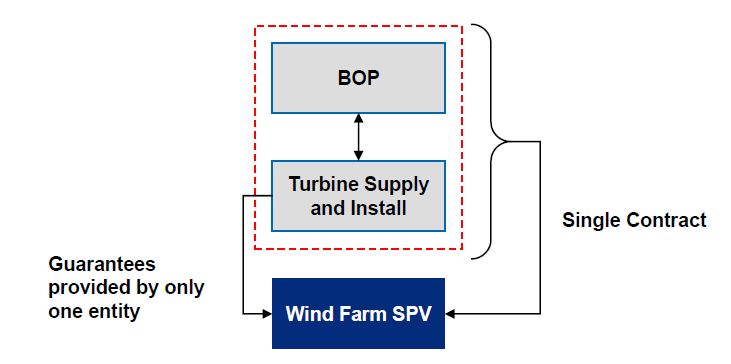

Another option is an EPC structure:

In this case, we will have a fixed price and fixed delivery date, with no interface risk and a single point of contact for the developer.

On the downside, the price will increase as the wrapping entity will add his margin for taking the risk. Moreover, they are more complex and time consuming with an heavy legal cost.

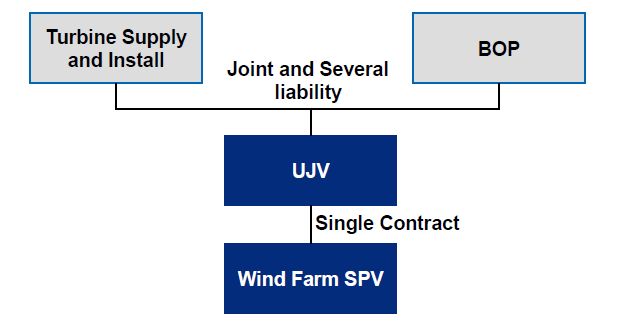

The third option is an unincorporated joint venture:

In this case the subcontractors will delivery a project without the requirement to form a separate legal entity. There is a single contract between the wind farm developer and the consortium of suppliers.

This structure has the same advantage of the EPC (fixed price and delivery date, reduced interface risk) but additionally there is a greater security thanks to the exposure to balance sheets of all the company in the consortium.

Disadvantages: increased price, heavy documentation costs and complex coordination work.

Leave a Reply