Some years ago I posted an article about a self-lifting wind turbine tower.

The idea was to use using heavy lift strand jacks already available in the market to lift the concrete sections of a wind turbine tower. It’s a project developed by Esteyco, a Spanish engineering company.

Well, I just discovered that it’s not the only idea currently under development on this topic – another company (curiously from Spain as well) is studying a somehow different concept with the same objective: avoid using big cranes, above all in areas of difficult access.

The product is called Nabralift – you can read more on the company webpage.

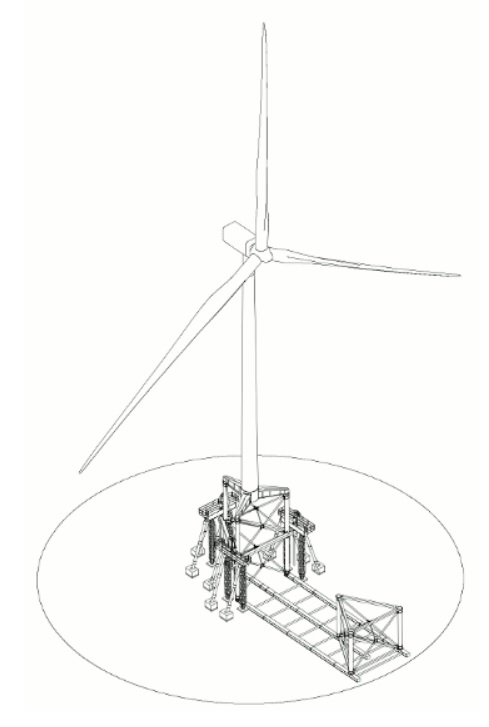

Basically it’s a tower with a mixed technology “standard” tubular steel + lattice where the steel section is erected by a standard auxiliary crane (like in the pre-erection of the first section) while the lattice elements are “pushed” little by little from the bottom by hydraulic jacks (this is a similarity with the solution discussed in the other post).

Apparently the solution doesn’t use an anchor cage – instead what I see from the pictures look like an adapter between the steel and the lattice section.

The company stated that they are undergoing a 6 months long fatigue test on a full scale model already erected in northern Spain.

Theoretically, there are 3 possible sources of saving here:

- Installation cost (no main crane)

- Tower cost (the lattice segment is proportionally cheaper than a standard steel one of the same height

- Foundation cost (apparently this solution will need a smaller foundation).

Last but not least, the increased stiffness of the lower part could lower the self resonance risk due to the passing blades, frequent in the very high towers currently in the market.

UPDATE 11/04/2020

I see that in the meanwhile a full scale prototipe has been built (video below) and that commercial operations started, with a first installation planned in Morocco this year.

I wish good luck and all the best to the Nabrawind team.

Leave a Reply