I have received a question from a reader regarding blades damaged by lightning.

Specifically, the blade has been damaged before commissioning.

At first sight the consequences could be less significant than usual, above all if the main crane is still on site and there is a set of spare blades available as happens frequently in big wind farms.

I would also guess that the turbine supplier will have to absorb the cost unless the risk was already transferred to the customer.

I would also like to elaborate a bit more on the topic as lightning is a frequent cause of damage to wind turbines (specifically to the blades, as they are hit in around 75% of the cases).

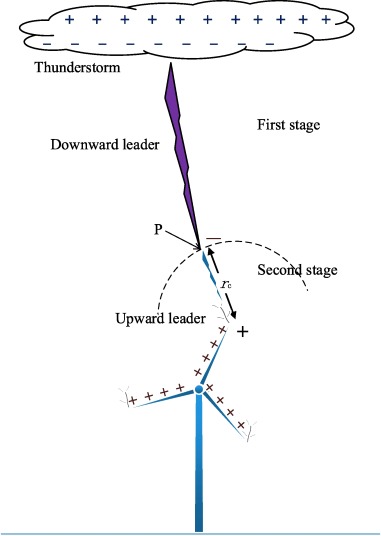

Lightning are created by the electric field between the bottom of the clouds (negative) and the ground (positive).

The potential difference is significant (some MV). However, due to the distance, the average electric field is weak.

As the electrical charges at the bottom of the clouds accumulate a “downward leader” (a channel permitting the flow of negative charges) start moving toward the ground.

If this stepped leader is somewhere nearby a wind turbine (or another similar structure) the second phase of the phenomenon may start: an “upward leader” from the blade connecting with the downward leader and closing the circuit.

This is the instant where the “return stroke” start and you usually see the majority of the light.

Coming back to the blades the standard technical solution consist in embedding a copper receptor connected to the ground at approximately 1 meter to the tip. This receptor has a diameter of at least 50 mm (pretty much like the copper cable used in the earthing of the foundations).

The problem is that this solution doesn’t works always: sometimes the lightning hit another point of the blade. Even if the surface of the blade is supposedly non conductive it has been observed that, due to the presence of pollution and water, it can behave like a conductor.

Leave a Reply