The braced foundation is a partially precast foundation that lift the wind turbine some additional meters above the ground.

Developed and patented by Esteyco (a Spanish engineering firm) is a technical solution validated, certified and used in several wind farms worldwide.

This solution increase the hub height up to 5 meters, which usually results in a significant increase of the annual energy production.

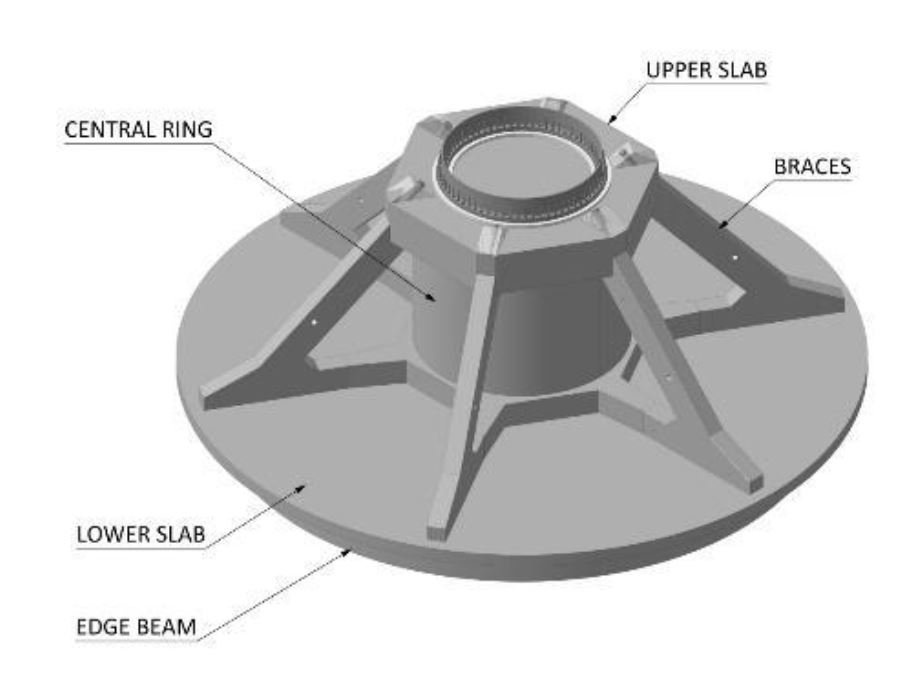

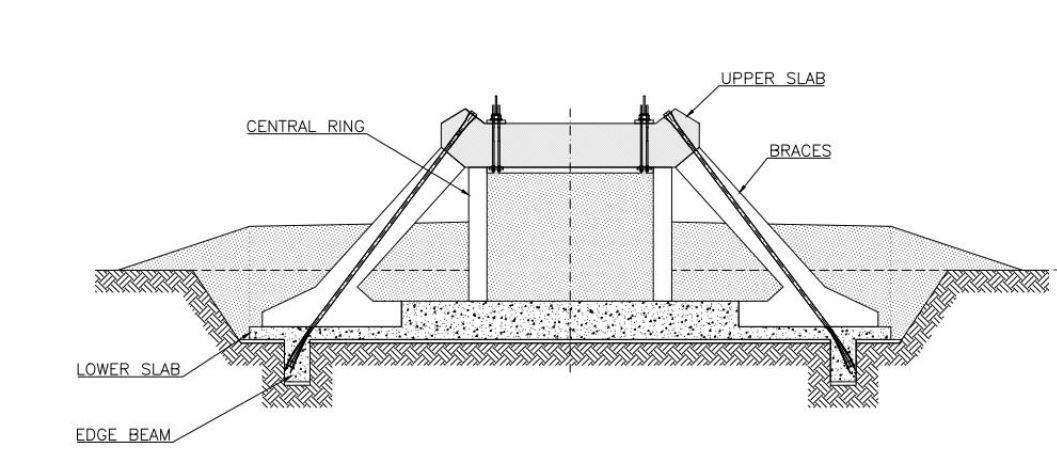

The “braces” are elements of precast concrete – basically double beams with a rectangular section transmitting the loads from the tower and stiffening the foundation.

They are on top of a cast in situ circular concrete slab that transmit the loads to the ground. This slab has a circular edge beam below, whose function is to absorb bending moments and contribute to the overall stiffness.

In the middle there is a central ring, while the tower rest on a smaller upper slab.

The main benefit of this solution is the increase of energy production – 5 meters of additional hub height can bring an annual increase in the 1% to 2% range depending on local wind condition.

Although this could look like a small number, compounded over 25 to 30 years it can really make a difference for the economics of the investment.

You first question could be something like “why not to use an higher tower”?

Generally, towers are designed, manufactured and sold with specific heights. Each wind turbine manufacturer has a portfolio that include only some heights (e.g. 90m, 100m, 110m, etc.).

Therefore you could find yourself in a position where the project could theoretically use a different hub height not offered by the wind turbine manufacturer.

Although every now and then project specific tower are designed and built this is not the standard and it has several implication in terms of time, cost, etc. Therefore it could be better to go for an off the shelf solution that gives you those additional few meters that your project need.

According to Esteyco this solution is also quicker to execute, at least in big wind farms. I do not have real world feedback to comment on this, although my impression is that the number of precast or partially precast foundation solutions used in the market is increasing.

This solution as a certain versatility because it can be used with different soil condition, including difficult geotechnical situation that needs piles.

It also use less material due to its geometry. I do not have actual figures to comment on the final cost, however my impression is that the real benefit will come from the additional production and that the saving in materials will be offset by the increased manufacturing complexity.

This solution has already a certain track record. I see that it has been used in Italy, Mexico, India, China and Saudi Arabia (in Dumat Al Jandal, a wind farm that I tendered 8 or 9 years ago – this gives you an idea of how long it may takes for a project to materialise).

It has also been certified by DNV-GL and TUV, undoubtedly a strong plus.

All the pictures are stolen from the presentation that Esteyco has given at India Windergy 2017.

Leave a Reply