I have discussed in other posts why wind turbines blades are prone to different type of damages and how to detect them.

But what happen when a problem is identified?

Changing the blade is usually the “last recourse” option: in addition to the cost of the blade itself there are the transportation costs plus the need to fine a main crane for the job (and it is not easy to find a free slot for a crane: due to their cost owners try to keep them busy 100% of the time).

Therefore efforts will be made to repair the damaged blade with a short downtime – ideally one or two days.

The technique used to fix the blade will depend on numerous parameters such as the entity of the damage (cosmetic, structural or affecting the efficiency of the blade), the region of the blades that suffered the damage (some areas such as the leading edge are more critical) are and the type of problem (cracks, debonding, impact damage, etc.).

Among the repair techniques currently used it is worth mentioning:

- Filling and sealing (also called “dill & fill”). With this solution small superficial cracks, delamination and other similar non-structural problems can be repaired injecting the appropriate material (usually resin, or special fillers or gel). To do it injection holes going to the depth of the defect are created. Often the resin is pre-heated before being injected with manual guns or pneaumatic tools using compressed air. The material injected can have a curing time of several hours or even a day. Curing can be at ambient temperature or at a higher temperature depending on the chemical properties of the substances used. In case higher temperatures are needed heating blankets or similar tools such as ultraviolet lamps (UV) are used.

- Coatings, tapes or shields. These solutions are especially designed for leading edge erosion repair and protection – a classic and frequent problem. Basically the idea is to use an additional layer to protect the leading edge.

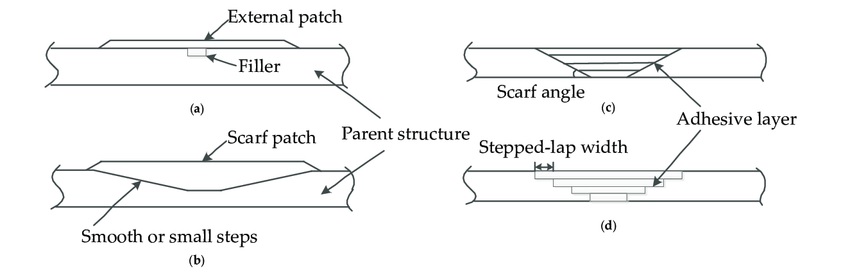

- Plug/patch and scarf repair for major damages. This solution involve removing the damaged region, leaving a straight, stepped or, if possible, tapered hole. Subsequently the patch is applied to close the hole. There are different alternatives for the patch: it can for instance be formed from a pre-impregnated composite fibre tape cut to shape, applied in layers using intermediate layers of adhesive or preformed to the correct shape and subsequently bonded.

(D. Lekou)

The adhesive used in blades repair is usually especially designed for this type of application. It has to be resistant to fatigue and cracks and have a short curing time (although for wind turbines located in extremely hot environments a slow curing adhesive can sometimes be a better choice). Two-component adhesive are frequent (basically the blade repair technician mix the two different components of the adhesive, activating the reaction).

Different repair works may be needed if the damage has be caused by lightning (a frequent occurrence) or if the problem is with the ancillary elements of the blade (like the vortex generators).

Leave a Reply