We try to design cable trenches as straight as possible, avoiding pronounced angles.

There are several national norms on the minimum bending angle, for instance UNE 20435/2 in Spain.

For environmental and technical reasons we try to design the trench parallel to the access road. When we have to cross an obstacle such as an existing asphalted road or a river, a standard solution is the horizontal directional drilling (HDD). We also try to limit the number of times we have to cross the internal roads, and when the cross section of the road is on halfway (with cut on a side and fill on the other) we put the cables on the cut side.

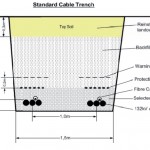

The depth of the cables seeks a balance between 2 factors: heath dissipation (easier when the cable is near the surface) and humidity, normally increasing with the depth.

Normally the cables are buried directly in the trench: only when they cross a road or enter the WTG trough the foundation they are protected with a plastic pipe (a standard diameter is 16 cm). In this case, it is normal to leave an empty pipe as a backup.

Regarding manholes several wind farms use them (for instance I’ve seen a number of Gamesa wind farms with manholes), while Vestas don’t consider them necessary.

We also mark with concrete milestone the position of the cables, to find them again when the vegetation growth.

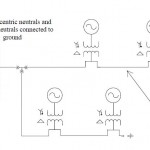

Below you can find an example of the single line diagram we use to work and a standard cross section (proposed for a project developed by Dong).

Leave a Reply