Concrete towers are still an uncommon solution nowadays, basically they are still more expensive than they steel counterparts.

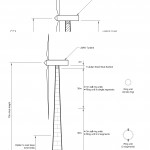

But the trend we see in the market is toward highest tower, of 100 meters and above, while current 2MW-3MW turbines normally have an hub height around 80 meters: this can lead to situation where an hybrid solution (concrete base plus steel top) or even a full concrete solution is finally economically profitable.

The reason for this increase in tower size is the need to increase the productivity (the wind speed increase exponentially with the eight) and to overcome surface friction, although it must be noted that almost every country has laws to limit the height of the tip of the rotor (on average, around 100 meters).

The biggest problem of tapered steel towers is that they maximum dimension in onshore wind farms is limited by transport issues: normally the biggest diameter allowed to circulate on public highways is below 5 meters, due to the free height of existing bridges. Tallest towers need bigger diameters, so there is a legal/technical limitation to the use of steel.

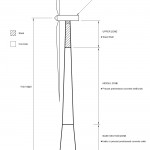

Several turbine manufacturers (for instance Enercon, GE and Nordex) have full concrete or hybrid towers in their catalogue, normally with eight above 100 meters. Often different sections are considered for the purpose of strength and stiffness design, fabrication and erection:

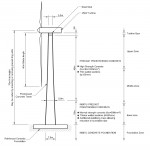

- Base zone, made of thick walled precast concrete segments or in situ concrete. Here the thickness can be around 40-50 cm.

- Middle zone: here the wall thickness is determined by concrete cover to reinforcement rather than by the necessary strength and stiffness, so a saving in material is possible.

- Upper zone: here the wall thickness will be around 10 cm only. It normally includes a steel section of about 2 meters to connect the yaw ring and the nacelle.

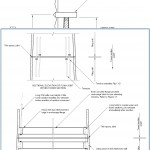

Various configuration, techniques and details have been proposed, all of them normally considering the use of vertical prestressing. It is normal to see solution with concrete rings divided in 2, 3 or even 4 segments, assembled and joined together in situ with 2 type of joints (vertical and horizontal) using mortar, fishplates or other technical solutions.

The weight of the components is really high: can be 50+ tonnes (in some solution even more), so there can be cases where it is more difficult to lift a tower section than the nacelle.

Several documents with conceptual design of concrete wind tower are freely available on the web.

Check for instance:

Concrete Towers for Onshore and Offshore Wind Farms

Competitive_Concrete_Foundations_for_Offshore_Wind_Turbines

Leave a Reply