How to optimize the design of WTG foundations?

As wind turbine loads and foundations size keep increasing year after year sharpening the geotechnical calculations and modelling correctly the interaction between soil and foundation is becoming a priority.

The cost of foundations can represent a significant percentage of the investment in a new wind farm – even more in 2021, when steel and concrete are becoming every day more expensive.

An important topic that is becoming the focus of detailed studies is the soil bearing capacity degradation under cyclic loads.

This subject has been incorporated in the new version of the standard IEC61400-6 on Wind energy generation systems in Part 6: Tower and foundation design requirements.

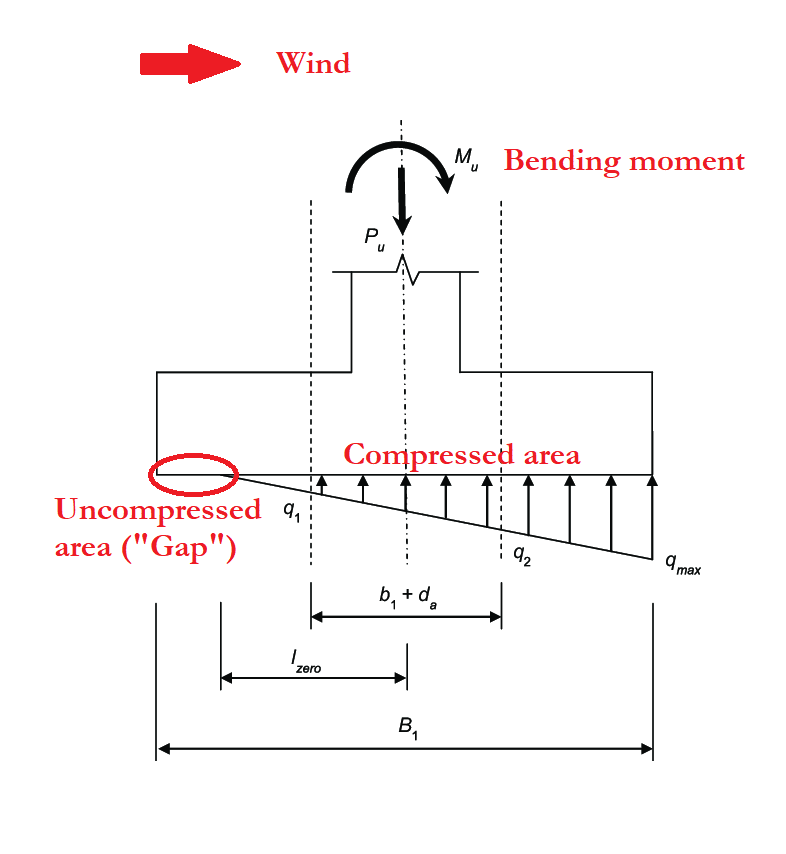

Now, under certain conditions, a certain amount of “gap” below the foundation may be allowed.

“Gap” means that under certain situations the ground below part of the foundation might become uncompressed – as if the foundation was partially lifted, creating a “gap” (i.e., a separation between the structure and the soil).

This is something that previously was not allowed (unless the foundation was on rock).

The reason is that if the soil goes through several cycles of compression and decompression its bearing capacity might deteriorate. Basically the bearing capacity becomes lower and lower, putting at risk the stability of the structure.

This is a relevant change, as the IEC standard is one of the most important document (if not the most important) used in wind turbines foundation design.

The key idea behind the change is that if the soil below the turbine is not susceptible to the phenomenon of degradation under cyclic loads a certain amount of gap can be allowed.

Removing this “no gap” requirement means that a significant reduction in the diameter of the foundation can be achieved.

This happens because otherwise the foundation would have been bigger only to keep the soil below it always compressed.

The “no gap” requirement used to be one of the dimensioning constraints in wind turbines foundation design when the soil was good.

The key to allow some gap in the foundation design (and as a result, a smaller foundation and savings in concrete and steel) is to be able to justify that the soil characteristics will not will not degrade under cyclic loads.

This involves dynamic tests, which are time consuming, expensive, difficult to implement on site, unusual for most geotechnical companies and difficult to post process and interpret.

In some cases, even with a robust testing campaign, additional finite elements models have to be created to validate the design.

Will we see smaller foundations after this change in the IEC? We will need to wait several months to answer this question.

Leave a Reply