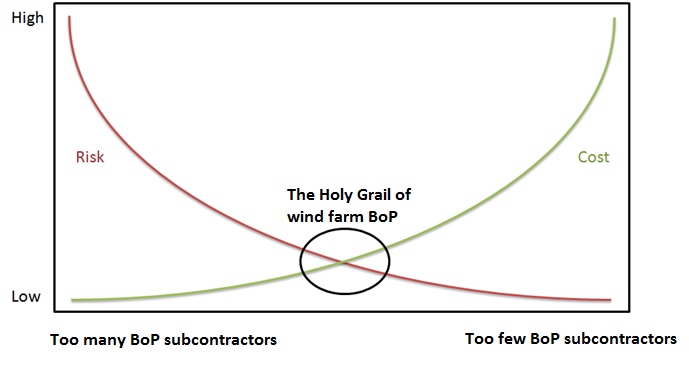

Itemized sourcing is the new mantra in the business. Basically, it means that you should split the BoP (Civil and Electrical works) in as many lots as possible, in order to achieve substantial savings. This strategy is the opposite of the “single subcontractor” approach, where you give the full package to a unique contractor or at least few of them.

What are the benefits of itemized sourcing? In addition to the possibility of achieving a lower price you also have more control on the purchase of critical items (for instance the main transformer).

Additionally, our friends in Procurement (for instance my role model Ignacio) can create PowerPoint slides showing huge savings to the rest of the organization.

The untold story is that there is no free lunch. What you are achieving is simply a different risk profile for your project: if the truck driver destroy your transformer against a bridge that is a few centimeters too low or if the foundations are build in the wrong place (believe me, both example are from real projects) you will have an hard time to recover your losses – because you purchased the transformer by yourself, or because you have in your pocket many small contracts with low liquidated damages.

Let’s assume that you split a 10 ML USD contract in 5 smaller contracts worth 2 ML USD each.

You will be able for sure to achieve substantial savings. However several other things will happen as well:

- You should tender every smaller contract separately. Therefore an additional effort is needed from the Tendering Department and from Procurement.

- Some big subcontractors will decline the job, because the size of the job is too small for them.

- You will need to discuss the contract (at least) 5x times – 10x if you have more than one option on your table.

- Unless the applicable law for your contract is something like Sharia (with dispute resolution in Riyadh) you will not be able to claim more than 100% of the value of the contract (2ML) from them. However your exposure toward the customer will be 10ML plus the value of the turbines. If one of them has a problem your risk will be huge.

- In the real world is often not so easy to understand who is causing a delay. Sometimes there are concurrent delays, sometimes it was not clear who was expected to do a job, other time a finger pointing game start. The more the subcontractor, the more the risk.

- Lastly, during construction you will need (at least) 5x more effort from the Contract Manager – and for the Site Manager, Project Manager and all people on site.

Don’t get me wrong – I understand that sometime there is no real alternative to make the project fly. However, before you embrace the itemized sourcing of the BoP as the solution for all your problems, you should keep in mind the additional work (try to negotiate 10 contracts in parallel) and risk that you are taking on board.

Leave a Reply