This post is an extension of the previous short article I wrote some years ago on the characteristics of wind farms medium voltage system.

I wrote it with the help of my friend and colleague Kamran, who spent more than an hour answering my questions on the subject. Thank you Kamran!

The medium voltage network is one of the elements that compose a wind farm project, the other being foundations, earthworks, substation and high voltage line.

Some elements could be missing: I have seen several projects without substation, for instance in France where small wind farms were connected to the grid directly at medium voltage level. However, you will never see a project without at least several hundred meters of medium voltage cables.

Wind turbines generally produce energy with a voltage around 600V – 700V. Subsequently the voltage is raised by a transformer that can be located in the nacelle, at the base of the tower or less frequently externally in a small box near the tower.

The objective is to minimize the electrical losses, and several voltage level are theoretically possible – I have seen projects with MV levels varying from 12kV to 33kV and higher.

The objective to achieve working at the design of the medium voltage system is obviously finding the sweet spot that optimize Capex (what you pay for cables and transformers cost) and Opex (mainly the electrical losses that you will have in the cables), selecting a rated voltage compliant with local regulations and cable types that are commonly used in the country where the wind farm is located.

Cables are rated by their effective cross sectional area in mm2 – the greater the section, the greater the amount of current they can transport.

Standard sections frequently used in wind farms are 70, 95, 120, 150, 185, 240, 300, 400, 500 and 630 mm. Greater sections are commercially available but already the 400 to 630mm sections are hard to use in construction due to their weight and bending radius.

The bending radius is usually expressed as a function of the diameter. For instance, “10x D” would mean that the minimum bending radius is 10 times the diameter of the cable. This parameter is significant because you will probably need some narrow bends in your cable, for instance at the bottom of the foundation if the transformer is inside the turbine. Large binding radius can make the work at the construction site very hard.

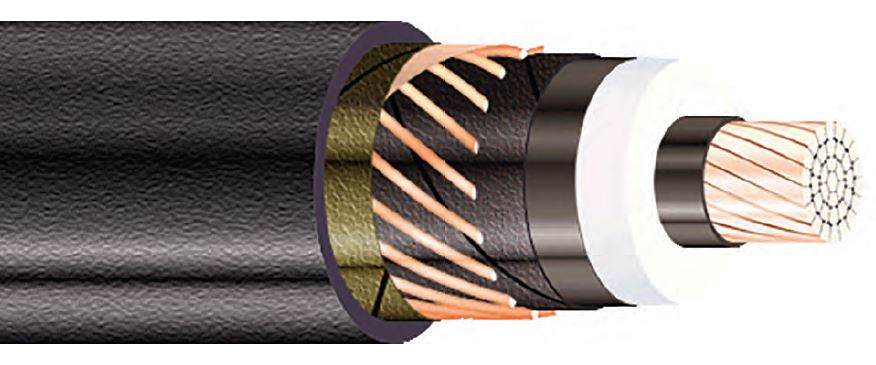

The cables are made of several layers with different functions – many technical alternatives and constructive techniques are available in the market but in general you will find (from the centre to the most external layer):

- A conductor core made of copper or aluminium

- An insulation layer, usually made of cross linked Polyethylene (XLPE)

- A metallic screen to stop the electric field

- An external sheath, protecting the cables from corrosion, humidity and mechanical stress. In some projects this most external layer is selected to have special properties such as for instance enhanced resistance to fire or protection from aggressive chemicals or even termites (I have seen this last feature in Australia)

Cables will be delivered to the wind farm in cable drums made of wood.

The standard design strategy is trying to minimize the number of cable drums because making the joints between different sections of cables is an expensive and highly specialized task.

There are however limits to the size of drums – basically both its weight and dimension must allow safe transport and manipulation.

The amount of meters of cable that can be transported on a drums depend on the cable type and diameter – for wind farms you will usually receive some hundreds of meters in each drum.

Single core vs. three core cables

There are two main typologies of MV cables commercially available, single core and three core.

In single core cables each comes with his own screen while in three core cables the three phases share a common metallic screen. If you select the single core technology you will need to use three different cables, one for each phase.

Aluminium vs. Copper cables

The material used for the conductor of the cables for wind farms is always almost always aluminium.

Theoretically, copper cables are available and copper has several desirable characteristics – for instance it is a more efficient electrical current conductor and requires a smaller cross section to carry the same amount of power as an aluminium conductor.

However, with the current relative prices of copper and aluminium, copper cables are simply too expensive so they are never used for the reticulation of wind farms – you will probably see them inside the substations, where distances are shorter.

The cost of raw materials such as aluminium represent a relevant percentage of the final cost of the cable. For this reason I tend to see the MV cables almost as a commodity.

Overhead vs. Buried cables

In the majority of countries, the cables are directly buried in a sand bed in the bottom of the trenches (or in very rare cases, inside a duct).

Every now and then, I see a project with an overhead medium voltage line, for instance in India or South Africa. However, they tend to be more the exception then the rule.

Leave a Reply