What were the consequences of the pandemic and the war in Ukraine on balance of plant (BoP) prices?

If you are reading this article, you probably know that the Balance of Plant (BoP) refers to all civil and electrical works necessary for the operation of a wind farm, excluding the turbines.

The BoP will therefore include elements such as roads, foundations, electrical cables, fibre optics, etc.

It is impossible to underestimate the effects of pandemic and war in Europe on wind farm infrastructure costs.

The cost structure of BoP varies depending on project characteristics.

For example, some wind farms connect to existing substations (or even in medium voltage), while others have to build a dedicated substation to evacuate the energy produced.

In some states, the electricity grid operator may oblige the project developer to also build an additional substation, that will be integrated into the existing grid. This is obviously a very onerous obligation, which may make the project economically unfeasible.

In terms of civil works, the scope of the project may also be very different: a 10-turbine wind farm built on top of a mountain (where the rock normally emerges after a few metres of excavation) will have significantly cheaper foundations than a wind farm in a valley near a river, where clay and other soft soil accumulated through the years and it will be necessary to use deep pile foundations.

The same wind farm in the lowlands, however, will perhaps be realised with cheaper roads (since it is a flat area), while its counterpart in the mountains may need massive earthworks.

Projects often also include the construction of one or more buildings for the control of the substation, the wind farm and the maintenance of the turbines.

These three activities can be carried out in a single building, although it is more common for the buildings to be physically separated. The reason for the separation is that the activities are carried out by personnel from different companies (the grid operator, the company that owns the wind farm, and the company that maintains the turbines, respectively).

Finally, as far as the medium voltage network is concerned, cables are normally underground, although in some cases overhead lines (which are normally cheaper) can be used.

To sum up, it is impossible to generalise and define a standard cost structure.

However, it is possible to identify the most frequent cost drivers and to discuss their evolution in recent years.

For civil works, these are usually concrete, iron, earthworks and buildings.

For electrical works, the main costs are generated by medium voltage cables, the transformer and other substation equipment.

How have prices evolved in recent years?

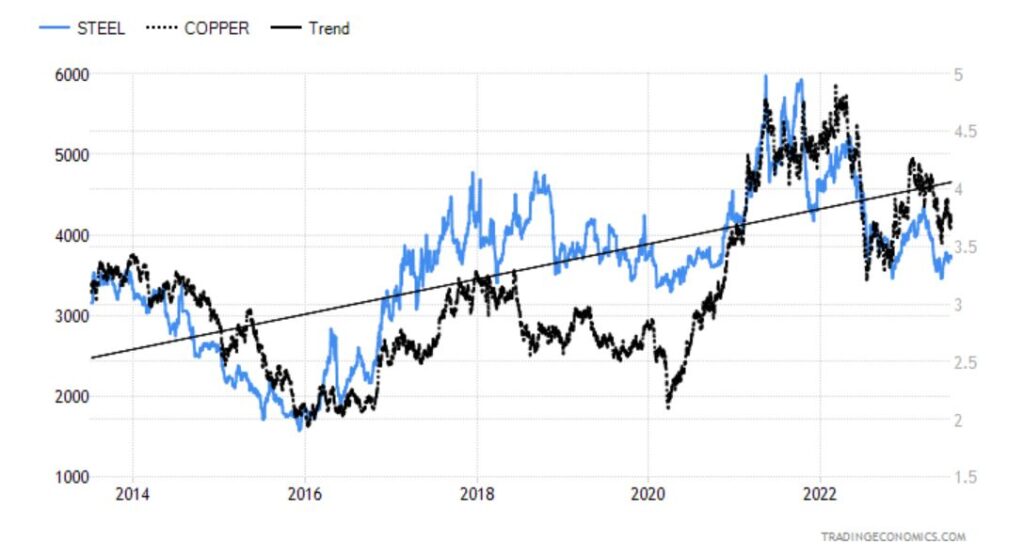

Steel prices rose rapidly in the post-Covid phase.

The Russian invasion of Ukraine exacerbated the situation: a significant amount of the steel used in Europe was in fact produced in Ukraine (the name Azovstal probably rings a bell).

In the first half of 2022 it was very difficult to find construction steel. Now the situation seems to be slowly improving, but I suspect it will be difficult to return to pre-Covid prices (if only because high inflation has developed in the meantime.

Copper, used in cables and for grounding turbines, has also followed a similar trend as steel.

Cement, a key component of concrete, has followed a similar evolution. An important part of the price increase is concentrated in the last two years, after a period of relative stability between 208 and 2014 and a slow increase between 2015 and 2021.

As a result, the cost of concrete has continued to rise – in mid-2023, as I am writing this article, it does not appear to have started to fall as the price of steel has.

Even a material with as little appeal as ordinary building bricks has risen by around 20 per cent in the last two years, and the price – despite rumours of a recession – does not seem to be stabilising.

Finally, the substation transformer(s). These elements, in addition to having experienced a comparable price increase with the other BoP elements, also have significantly longer manufacturing times than they used to have a few years ago. In some cases, they can go so far as to make the realisation of the project in a reasonable time extremely problematic.

Leave a Reply