In previous post some years ago I have described two alternative solution for the wind turbine tower that should help solving the problem of the huge cranes that are currently needed for the erection of the wind turbines components.

One is the self-lifting precast tower developed by Esteyco, a Spanish engineering company that developed several interesting technical solution.

The other is the Nabrawind solution – again, a Spanish company that developed a self-erecting tower. They also have another interesting product, modular blades that can be assembled.

Some days ago, I have discovered another technical solution that share some similarities with these two concept but with an interesting twist: a group of Italian engineers has developed a “retractable” tower, basically a telescopic mechanism that can be folded bringing the blades down to the ground without using cranes or other equipment.

Theoretically it could be operated from a remote location, even if I guess that some kind of supervision during the operation is advisable.

Why should you want to make your wind turbine disappear?

The authors mention several reasons, for instance minimization of the visual impact (you can make your WTG almost invisible during the day and having it work at night).

I can also think at other uses – minimization of bird impact (folding the tower during the migration period) or increased safety during extreme wind (for instance during the monsoon season in south east Asia).

The idea is not only a concept –a working prototype has already been built in southern Italy.

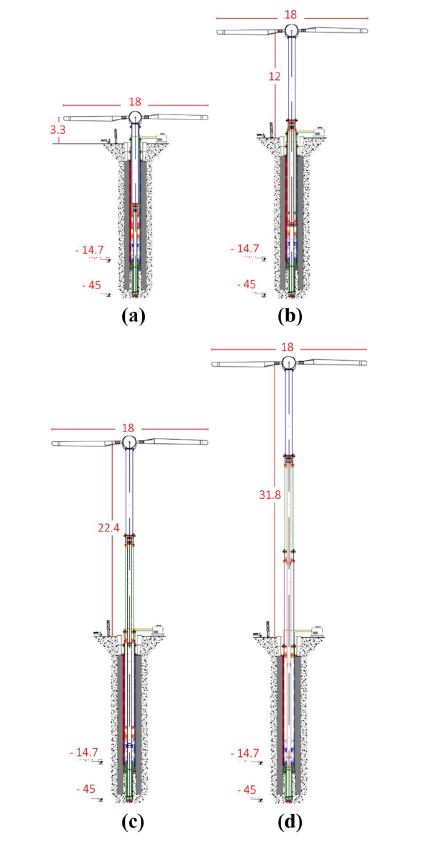

It is a small wind turbine (55 kW), at least for what is today the standard in utility scale projects (3 to 5 MW). Additionally it has only 2 blades, which I think can help when you retract the tower.

However the hub height is 30 meters, quite a reasonable figure.

It is interesting to observe that this technical solution needs a deep foundation, basically with a depth equivalent to the hub height.

It is mentioned the possibility to modify the concept to use the foundation hole as a well to extract water. Quite an interesting side benefit I would say.

The authors are not sharing the cost of the tower and the ancillary elements, although I suspect they could be several time the cost of the standard, non-retractile tubular steel tower.

Finally, it would be interesting to know the applicability of this solution to WTGs in the MW class.

The authors mention a dimensioning bending moment of around 300 kNm. Such value is two orders of magnitude lower of the values that are common in industrial size turbines, so it is not immediately evident that the idea can be scaled without major modification.

An additional problem would be the length of the foundation pit. Reaching depths of 50 meters and below, although not impossible, introduce new issues – for instance the need of very specialized drilling equipment.

Leave a Reply