I’m currently having the pleasure of working at a wind farm project in Senegal.

One of the challenges I’m facing is the use of unconventional materials, at least based on my European background.

For instance, the internal roads and crane pads will be probably made of laterite, a solution very common in tropical climates successfully used in several countries for the subbase and base layers.

These days I’ve been investigating on the peculiarity and the technical requirements of this material.

As a starting point, I’ve selected the useful “Guide pratique de dimensionnement de chaussée pour les pais tropicaux”.

On page 36 you will find a catalogue of low traffic roads suggested cross sections. Considering the subgrade CBR of the wind farm site, I’ve selected 2 layers of 35 cm (foundation) + 15 cm (base), both made of laterite.

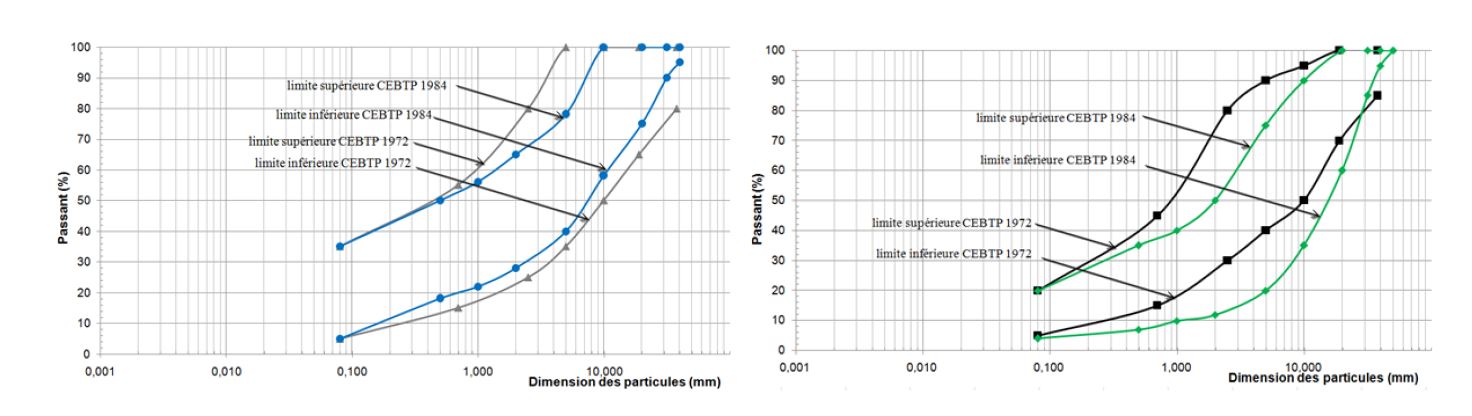

The granulometry can be found at page 60 (foundation) and page 73 (base).

There is also a requirement about the maximum increment of fine particle percentage (less than 8%), while the PI is greater than normal (<15).

Finally, you’ll also find that maximum CBR swelling is 1%.

The document “Characterisation of laterite for road construction”, from where I’ve stolen the graphs above, explains that compaction can greatly change the granulometric distribution of this material. Therefore, it is wise (although unusual) to ask for a granulometry check after compaction.

Another useful research is this “Review of Specifications for the Use of Laterite in Road Pavements”. The authors suggest using the Brazilian standards. You’ll also find an extended bibliography, a detailed analysis of the criteria followed in several countries and “real world” results on existing roads in numerous countries.

Leave a Reply