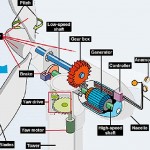

Blades: Most wind turbines have three blades, though there are some with two blades and even with a single blade. Blades are generally 30 to 50 meters (100 to 165 feet) long, with the most common sizes around 40 meters (130 feet). Longer blades are being designed and tested, but the main problem with bigger blade is transportation. Blade weights vary, depending on the design and materials—a glass fibre blade of about 45 meters weighs more than 6,000 kg

Controller: There is a controller in the nacelle and one at the base of the turbine. The controller monitors the condition of the turbine and controls the turbine movement.

Gearbox: Many wind turbines have a gearbox that increases the rotational speed of the shaft. A low-speed shaft feeds into the gearbox and a high-speed shaft feeds from the gearbox into the generator. Some turbines use direct drive generators that are capable of producing electricity at a lower rotational speed. These turbines do not require a gearbox.

Generators: Wind turbines typically have a single AC generator that converts the mechanical energy from the wind turbine’s rotation into electrical energy.

Nacelles: The nacelle houses the main components of the wind turbine, such as the controller, gearbox, generator, and shafts. It is made of fibreglass and it is equipped with several sensors. It is normally produced in house, while sometimes tower or even blades are outsourced.

Rotor: The rotor includes both the blades and the hub (the component to which the blades are attached). Standard diameters used in this years are from 80 to 115 meters.

Towers: Towers are usually tubular steel towers 60 to 80 meters (about 195 to 260 feet) high that consist of three or more sections of varying heights. Several companies use concrete or mixed (with a concrete section and a steel section) towers, above all where the price of steel is very high (right now in Brazil).

Leave a Reply